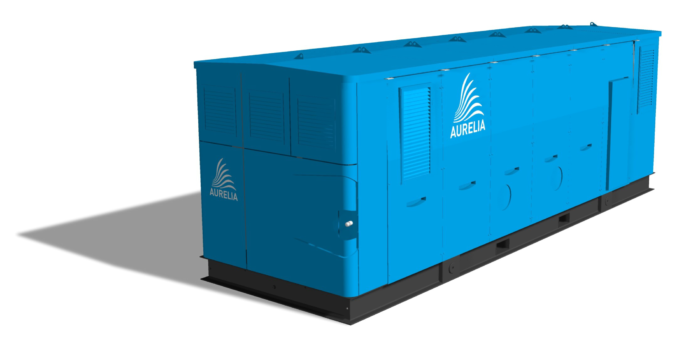

We offer the most efficient small gas turbines in the world made by the company Aurelia. Their turbines enable simple and efficient electric generation for small and medium size industrial processes and their modular design allows maximum flexibility. Aurelia’s combustion process has been developed to use natural gas, syngas, renewable and other non-standard fuels.

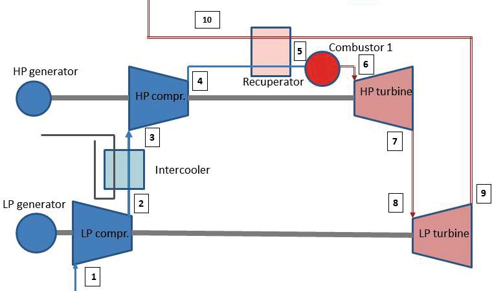

The Aurelia™ A400 provides 400 kWe with an electrical efficiency greater than 40 %. The turbine is a twin-spool, intercooled and recuperated (IRG2) gas turbine. The turbine is of modular construction and is designed to utilise a wide range of fuels, from standard liquid and gaseous fuels to biogas, biodiesel, flare gasses and even synthetic and recovered gases.

Product features and benefits

- modular design

- active magnetic bearings

- single-can combustion chamber

- remote monitoring

- high speed power generation

- highest electrical efficiency in class

- worldwide service network

- no lubricants, no friction, no wear

- low emissions

- zero vibration

- indoor and outdoor installations

- minimal maintenance and dow-time

- integrated inlet air filters

The most efficient small gas turbines in the world

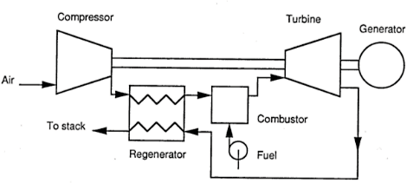

The technology builds on the classic microturbine process,

providing excellent efficiency gains over the competition

Ordinary, 1-stage recuperated microturbine New, 2-stage turbine process with two separate shafts and two generators

The process itself is well-known & demonstrated. However the technologies that enable this process to be used are new. Aurelia has extensive immaterial rights on these technologies.

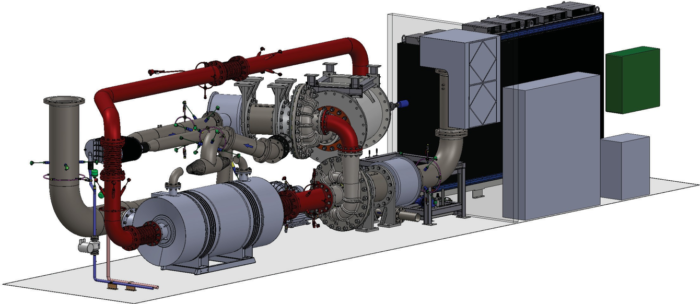

Modular design enables easy maintenance

and big amount of 3rd party components provide reliability from the beginning

- industrial combustion chamber able to utilize large variety of fuels

- off-the-shelf, tested and proven converter/inverter train

- industrial recuperator

- two turbine shafts – only components manufactured by Aurelia