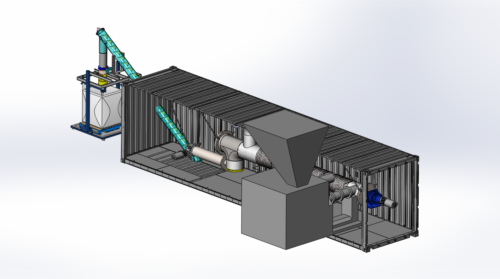

This pyrolysis system is focused on maximum yield and highest quality of liquid fraction during thermal decomposition of this material at the expense of input power. Ideally, this option means that after thermal decomposition of sorted and crushed waste plastics, we can obtain up to 90% by weight of the process liquid of the highest quality, ie. up to 750 liters of process liquid. The obtained process gas and the solid residue are then contained in the remaining volume of the obtained products almost equally.

The input power of such technology is max. 750 kg/hr. in continuous operation.

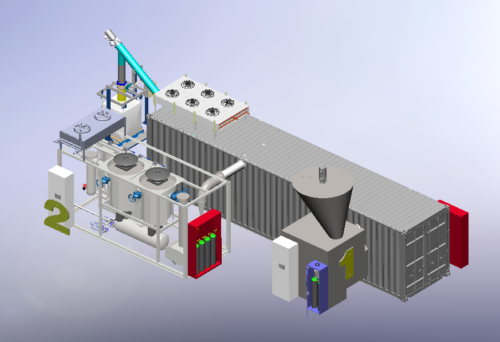

For this variant, the technology is equipped with two low-temperature reactors and two additional low-temperature evaporation tanks. The whole system is heated by direct-heating resistors with active electronic thermostatic regulation.

The total installed power input of this version of the technology is 170 kW, the operating electricity consumption is at a maximum output of about 80 kW/hour.

Reactor module and condensation of depolymerization technology

The individual volumes of the products obtained depending on the conditions described within the range:

- syn gas -> 5 to 36 % by weight

- oil -> 30 to 55 % by weight

- solid intert residue -> 28 to 45 % by weight