Our solution of transforming plastic waste and waste tires into highly valuable outputs uses technology called thermal depolymerization or better known as pyrolysis.

The pyrolysis process uses sorted shredded waste which is decomposed at high temperatures in a retort without air so the waste does not burn and does not produce any harmful emissions.

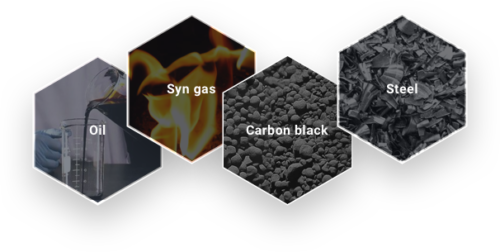

Our pyrolysis system transform your waste into different feedstocks for commercial use: